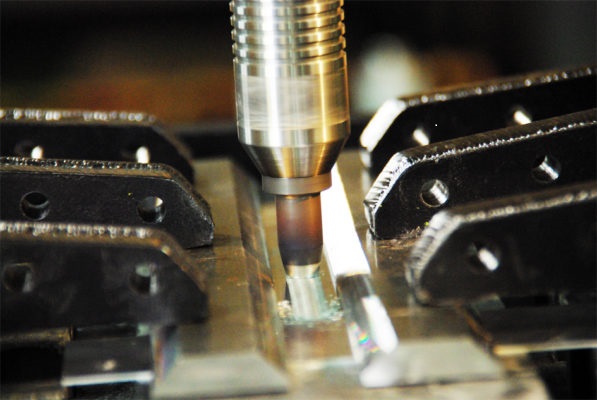

Stirweld’s FSW head uses a NC machine tool for FSW. This innovation reduces drastically the investment cost to access to FSW while offering performances identical to a special FSW machine.

Our products:

FSW head for NC machine tool: low investment cost, adaptability, ease of use and installation

FSW tools: low cost, higher quality, more efficient

Turnkey solution: parameters, jigs, training

Advantages

- Low investment cost: compared to FSW special machines or robotic stations

- Adaptability: Despite the lack of standard machining centers, the StirWeld FSW head can be adapted to all MOCNs.

- Ease of use and installation: After the first installation, the user can assemble and disassemble the FSW head in a few minutes from machining to welding and vice versa.

Head features:

- Matching on 3 to 5 axis CNC machine

- Assembly or disassembly in 15 mins

- No hard or soft change of CNC machine

- Force control to secure the weld quality from 1 to 18 kN

- Water and air pressure cooling

- From welding to machining without head disassembly

- Small size to accomodate welding jig

- Self-lubricating: no maintenance

- CNC machine protection against the high forces (up to 18 kN) and vibrations during the FSW process

- Quick tool change (attachment with accurate positioning)

Technical sheet:

Size:

- Compliant part: height of 300 mm

- Interface: height from 60 to 110 mm depending on CNC machine

Weight: 30 Kg

Water cooling: 5 l/min at 25°C

Air pressure cooling: 3 bar

Head – console distance up to 10m (more in option)

Control Interface:

- Recording of forging force for quality control

- Temperature monitoring for safe use

- Real time display process adjustment or process control.

The tools are tested on a wear bench to control their reliability.